Why do explosions occur?

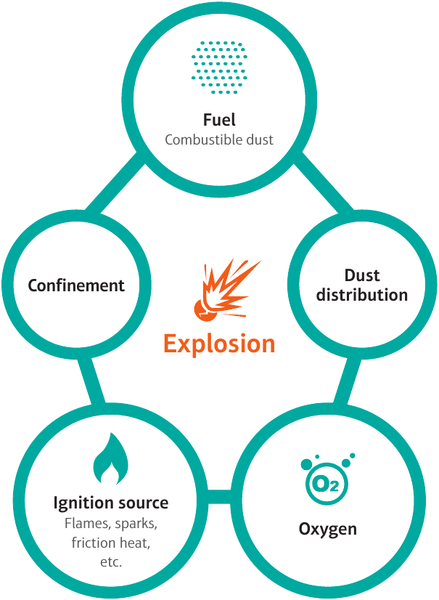

When a combustible material, an ignition source and atmospheric oxygen collide in a confined space, the result is an explosion. Preventative explosion safety measures aim to stop this potentially lethal mixture from occurring. However, in practice, the vast number of potential ignition sources alone almost always makes this impossible. Consequently, the most important safety features for industrial companies are protection measures that minimise the damage caused by an explosion. Industrial plants must always be protected against the consequences of explosions to ensure that employees are safe and production can be resumed quickly. After all, every hour of lost production costs money. In most cases, explosion safety can be provided cost-effectively through explosion venting and explosion suppression.

We will be pleased to show you solutions tailored to your processes that will reduce the damage caused by an explosion to a negligible level – enabling you to resume production quickly after an explosion.

The 3 key features of a modern protection concept

1. Reliability and productivity: Protection systems must be permanently available and operational. The possibility of false triggers must be excluded as this reduces the productivity of the plant.

2. Compliance: Modern protection systems must satisfy all legal requirements and thus guarantee legal compliance for plant operators.

3. Cost-effectiveness: Protection systems must be as simple as possible to install and require minimum investment of time and financial resources. The running costs of the systems must also be kept as low as possible.

All protection concepts from REMBE® meet these requirements. That's a promise!

Why is explosion safety so crucial?

Higher – faster – further: not just the objective in sport but also in the development of industrial plant technology. 21st century machinery has long been optimised and is running at high speeds. However, as plants approach their maximum capacity, the risk of an explosion also increases. Rising levels of fine particles produced by fast-running machines are one of the main reasons that the probability of an explosion has increased – these explosions almost always cost human lives. Even if nobody is harmed, an explosion in an inadequately protected industrial plant can still cause immense structural and financial damage. History shows that explosions in unprotected plants have driven companies to bankruptcy time and time again. After all, every day of lost production puts the company’s existence at risk. Explosion safety concepts usually enable businesses to eliminate production downtime entirely or at the very least reduce it dramatically – and with REMBE® products it is always more affordable than you think.

3 steps to make your processes safer

1. Risk assessment

A risk assessment determines the probability that an explosive mixture of dust and air (divided into zones) will come into contact with an effective ignition source. If there is a danger of an explosion occurring, you must take steps to prevent, or at least reduce the probability of this happening (see Step 2). Alternatively, you must implement a protection system that reduces the damage an explosion would cause to an acceptable level (see Step 3).

2. Prevention and organisational measures

- Technical measures: Effective dust extraction systems prevent the build-up of an explosive atmosphere (Rommel®). Inert gas blanketing is also recommended to reduce oxygen levels.

- Eliminate effective ignition sources:Only ever use the appropriate equipment (GreCon®) and prevent foreign bodies from entering the product stream. Check that equipment is correctly grounded to avoid electrostatic discharges.

- Organisational measures: Employees should always receive comprehensive training. Documented cleaning procedures and permit-to-work systems for hot-work create an additional level of safety.

3. Protective measures

- Explosion pressure resistant or explosion proof vessels: These terms are used to describe vessels, which are strong enough to withstand the maximum explosion pressure.

- Conventional explosion venting: Explosion venting is a technique for protecting sealed vessels that prevents the pressure within the vessel from rising above a permitted level. Breaking points, such as explosion discs or panels, in the walls of the plant rupture when the pressure reaches a predefined level and thus reduce the pressure in the vessel to a safe level.

- Flameless explosion venting: Essentially uses the same principle as conventional explosion venting. However, it offers the advantage that the explosion can be vented indoors because the flame and pressure wave of the explosion are contained. This eliminates the risk of injury even when working in close proximity to the equipment.

- Explosion suppression: Pressure and/or infrared sensors detect the danger of an explosion at a very early stage. Within a few milliseconds, a control system smothers the germ of the explosion using an extinguishing powder that is released into the plant.

Explosion safety measures also compromise of explosion isolation systems in order to prevent the devastating effects of explosion propagation or secondary explosions.